The Highest Quality

Masterbatch and PP Yarn Manufacturing

Sonali Group, Leading Innovator in Masterbatches, Additives, Polymer Compounds, and Multifilament Yarn

Since 2005, SONALI has emerged as one of the fastest-growing and most respected organizations in the industry. We specialize in offering a comprehensive range of high-quality Masterbatches, Additives, Polymer Compounds, and Multifilament Yarn.

Our journey began with a modest production capacity of 4,000 metric tonnes per annum. Over the years, we have scaled new heights, continuously upgrading our facilities to meet the growing demand. Today, we proudly operate with a production capacity of 75,000 metric tonnes per annum.

READ MORE ABOUT USProducts

Our Top Selling Products

We provide high quality, innovative and custom made solutions for a range of plastic products. Some of our best selling products are

Filler Masterbatches

Filler Masterbatches are manufactured with ultrafine Calcium Carbonate (CaCO3) in PE/PP/HD Based. The grades are available with polymer content ranging from 15% to 30%. Dosage of SONALI Filler Masterbatch can start from 15% to 45%. Read more on Filler Masterbatch

Color Masterbatches

SONALI is one of the most experienced producers and has a wide range of Colored Concentrates used in different plastic processing techniques/applications. These masterbatches are produced with a maximum loading of high-performance pigments. Read more on Color Masterbatch

Non-Woven Masterbatches

Non-Woven Color Masterbatches are developed with high-quality Pigments and Additives. We use special Additives for perfect dispersion of pigments and also give a high gloss effect on the Fabric. Read more on Non-woven Masterbatch

White Masterbatches

White Masterbatch, developed with ultrafine and ultra white TiO2 to provide better brightness and more whiteness to the product. It provides opacity and can be used with PE and PP. The range of White Masterbatches is available with Titanium dioxide loading of 20% to 75%. Read more on White Masterbatch

Black Masterbatches

The quality level of Black Masterbatches is ensured by the characteristics of Carbon Black it contains and the production processes. Black Masterbatches must possess a harmonious dispersion, blackness intensity and sufficient concentration levels. Read more on Black Masterbatch

Modifier - OJAS

OJAS is an elastomer based compound which works as a modifier, processing aid and excellent bonding agent. It facilitates property enhancement and cost reduction. OJAS is compatible with most of the polymers like HM-HDPE, LDPE, LLDPE, PP, PS etc. Read more on Modifier-OJAS

Additive Masterbatches

Additive Masterbatches add value to plastic production processes and provide qualification to the end product. Sonali Group produces a vide range of additives for various plastic processes and applications. Read more on Additive Masterbatch

Special Effect Masterbatches

Appearance can be an important aspect for some performance plastics. Special effect masterbatches usually include special pigments or fillers to achieve different visual effects such as marble, metallic, glitter, fluorescence, transparent etc. Read more on Special Effect Masterbatch

Roto Foam RF-05

Roto Foam RF-05 comprises a Linear Low-Density Polyethylene, formulated with a foaming agent suitable for rotational moulding. This grade is suitable for the water storage tank. It exhibits excellent bonding to a polyethylene skin in multiple layer tanks. Read more on Roto Foam

Market

A Selection Of Industries We Serve

Our superior understanding of how to connect businesses has always been paramount to our ability to operate and create value in every industry we serve

Our Brand

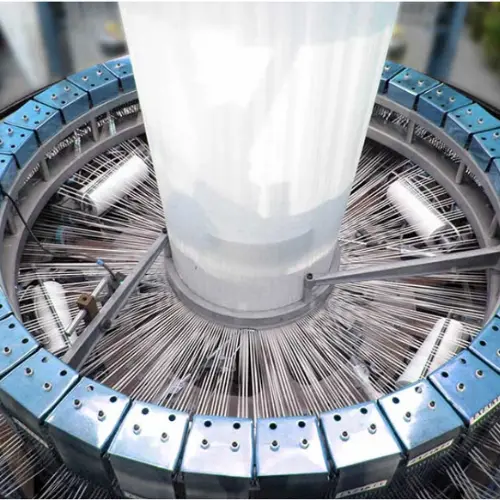

Weavlon

Incepted in 2021, the Weavlon plant is one of the biggest in Eastern India. We are offering multifilament Yarn & Stitching yarn in various types, colors, twists, and intermingles.

READ MORE ON WEAVLON

Why Choose Us?

Top Working Process

We are Efficient and provide right balance between design and deployment with Integrated Support. Our objective is to evolve systems and procedures for achieving consistent quality and constantly upgrade our products, processes and technology.

Customized Products

Shouldered by a highly qualified in-house R&D department we offer customised solutions to our customers.

Quality Support

We employ a system of extensive research and testing conducted rigorously to achieve the finest grade of products.

Export House

Our Dedication to quality is being lauded worldwide and we are the Government of India recognized Star Export House.

ISO Certified

The statement of our unwavering quality is our prestigious ISO 9001:2015 certification cementing our position as one of the best.

Latest

New Launched Products

Shouldered by a highly qualified and consolidated in-house R&D department, We are always developing new products to find solutions for complex challenges. Some of our new masterbatches are

THE INFRASTRUCTURE

Our Facilities

The manufacturing process relies upon both Single-Screw and Twin-Screw extruders, running on the sophisticated and efficient gravimetric feed system, capable of polymer extrusion and mixing and plasticizing abilities.

We boast a highly developed laboratory with the latest equipment and our modern state-of-the-art material handling infrastructure and facilities are capable of prompt and safe deliveries across the globe.