Desiccant Masterbatch

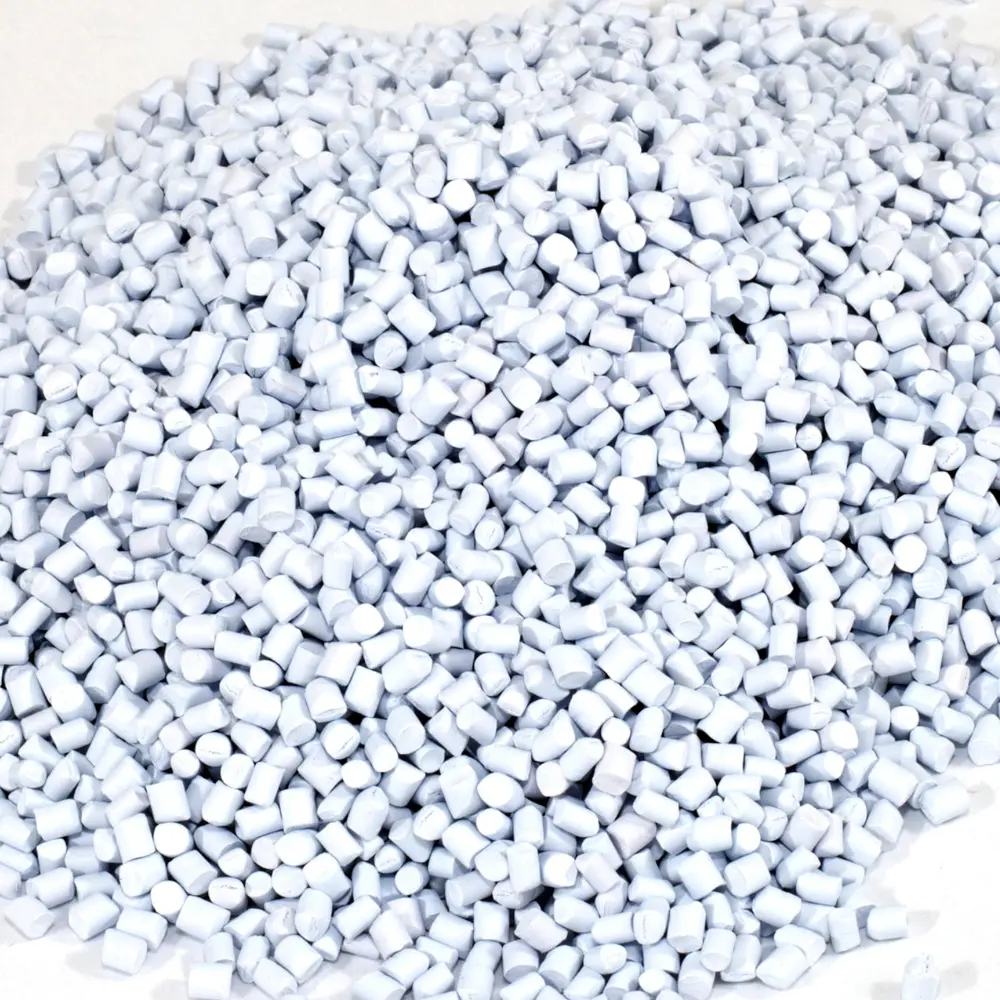

Desiccant masterbatch is non–toxic, non contamination and no influence to property for plastic products. It offers a simple and cost effective solution to solve moisture problems.

Desiccant masterbatch can counter problems which develop during the processing of plastics due to the presence of moisture. Moisture can be present in raw materials such as hygroscopic polymers, fillers and pigments. Reclaimed and recycled polymers can also have high moisture content. When processing polymer with high moisture content the polymer can become porous and show voids in moulded articles or extruded sheets. In film applications the high moisture content can lead to Lansing and film bubble breakage.

Desiccant masterbatch chemically binds moisture during processing and allows higher levels of reclaim or recycled polymer to be used; addition of higher filler levels; and can reduce the need for pre-drying in many applications. In the process of molding, desiccant masterbatches can strongly absorb the moisture in the plastic raw materials or other related plastic materials additives. It can increase product quality and the rate of finished products, improve productivity and reduce energy consumption.

Applications

Key Advantages

| # | Product | Grade | Applications |

|---|---|---|---|

|

1

|

Dessicant Masterbatch

|

MG1006 |

Molding , Tarpaulin

|

|

2

|

Dessicant Masterbatch

|

ADDM 111 |

Monolayer film , Mulch film

|

|

3

|

Dessicant Masterbatch

|

ADDM 131 |

Mulch film , Monolayer film

|

Share