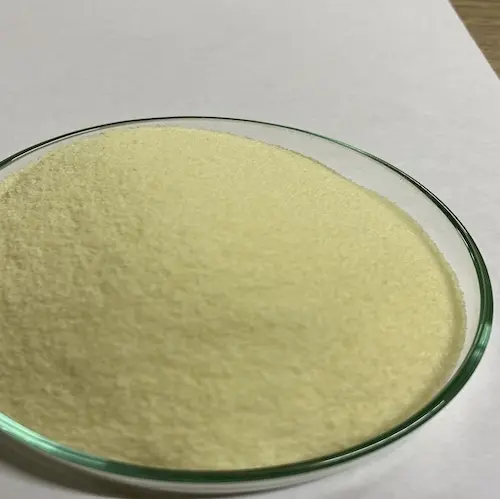

UV Masterbatch

Degradation is an undesirable process in most polymeric applications. It generally leads to changes in the chemical and physical structure of the polymer resulting in the loss of many useful properties. UV degradation of polymers can negatively affect molecular weight, impact resistance, elongation at break, gloss and colour. By incorporating UV stabilisers, the occurrence of such damages can slow down considerably.

Addition of UV masterbatch into the polymer mix, improves the appearance/aesthetics and the overall life of the product. They combat the degradation that polymers can undergo under the effects of sunlight, UV rays, heat, reaction with oxygen or fluorescent light.

Applications

| # | Product | Grade | Applications |

|---|---|---|---|

|

1

|

UV Masterbatch

|

UV AD10 |

Shade net , Tarpaulin

|

|

2

|

UV Masterbatch

|

UV 1002 | Silpaulin |

|

3

|

UV Masterbatch

|

UV 1005 |

Silpaulin , Water tank

|

|

4

|

UV Masterbatch

|

UV P1035 |

Raffia , Tarpaulin

|

|

5

|

UV Masterbatch

|

UV PE1015 |

Film , Raffia , Water tank

|

|

6

|

UV Masterbatch

|

UV PE1030 |

Water tanks , Mulch film

|

|

7

|

UV Masterbatch

|

UV PE1032 |

Water tanks , PPR Pipe

|

|

8

|

UV Masterbatch

|

UV PE1041 |

Film , Raffia , Molding

|

|

9

|

UV Masterbatch

|

UV PE1041/2 |

Film , Raffia , Molding

|

|

10

|

UV Masterbatch

|

UV PE1043 |

Film , Raffia , Molding

|

|

11

|

UV Masterbatch

|

UV PE1090 |

Cross laminated Tarpaulin

|

|

12

|

UV Masterbatch

|

UV PP1032 | PPR Pipes |

Share