Anti fog

An optical property in terms of high clarity without any fog on film surface as well as keeping the food item fresh is one of the most important properties of flexible packaging used for chilled food products. For the agricultural films too, one of the important properties for it is anti-fogging properties. The atmosphere within greenhouses or tunnels surrounded by an agricultural film is saturated with water vapour which evaporates from the soil or plants, and the water vapour dropwise condenses on the inner surface of a cold film to cause fogging. Water droplets on the film not only greatly reduce the incident sunlight due to irregular reflection but the droplets fall on the plants resulting in frequent occurrence of diseases.

Apart from anti fog coating on film surface, using of internal antifog additives will provide a cost effective and clean process for plastic film manufacturing. Our anti-fogging additives for plastics allow water to spread into a continuous and uniform transparent layer of water on the surface of films. This results in improved light transmission and transparency which has benefits in both agricultural and food packaging applications.

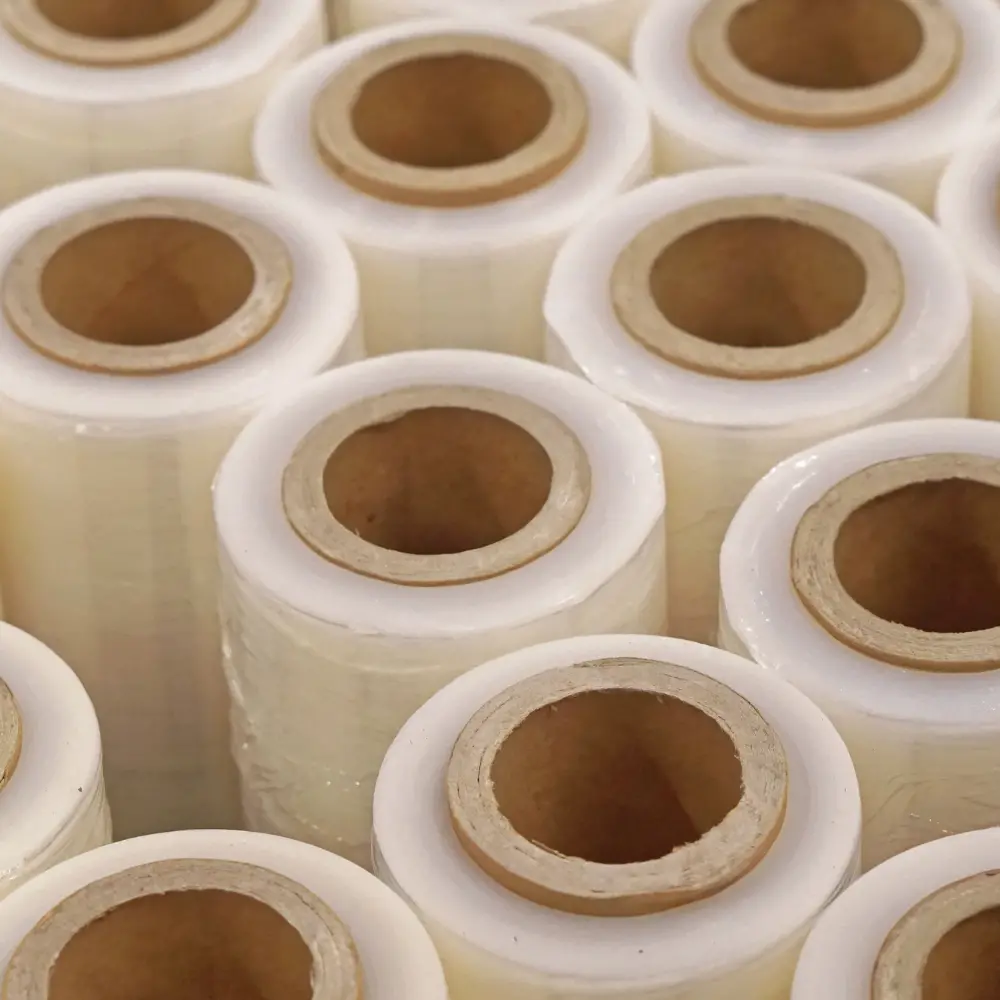

The anti fog masterbatch – high concentration anti fog agent in polyolefin carrier resins – has been successfully produced through a twin screw extrusion process. This continuous compounding process can incorporate a high content of anti fog agent in liquid form into molten plastic. The intensive (distributive and dispersive) mixing between anti fog and carrier resin was achieved by specific screw design and process parameters.

Our developed antifog masterbatch provides an outstanding anti fog performance with a high evaluated score in cold fog test was delivered in either single layer film or multilayer film.

Applications

Key Advantages

| # | Product | Grade | Applications |

|---|---|---|---|

|

1

|

Anti Fog Masterbatch

|

Anti Fog AF AD12

|

Green house film , Food packing film

|

Share