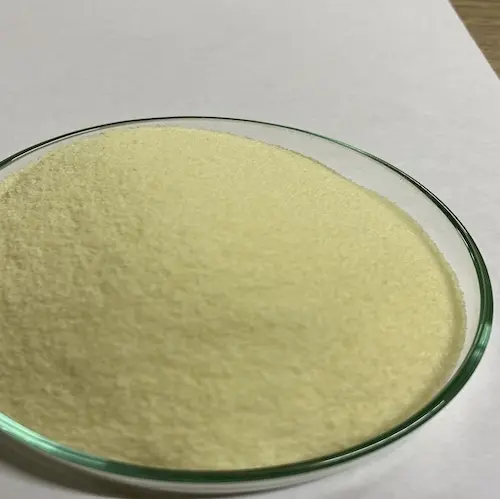

Anti Static

Plastics are insulating materials subjected to electrostatic build-up and discharge depending on the surface resistivity of the part. Plastics such as PP and PVC, tend to collect electrons and become negatively charged. Antistats are materials controlling the accumulation of static electrical charge especially on polymer surfaces.

This accumulation of charge at the surface makes the material prone to electric discharges, dust adhesion and static clings.

Antistatic Additives control the buildup of static charges in thermoplastic parts, enabling them to dissipate by absorbing and ionising moisture from the air, which forms a conductive path for surface static charges.

Application

Key Advantages

| # | Product | Grade | Applications |

|---|---|---|---|

|

1

|

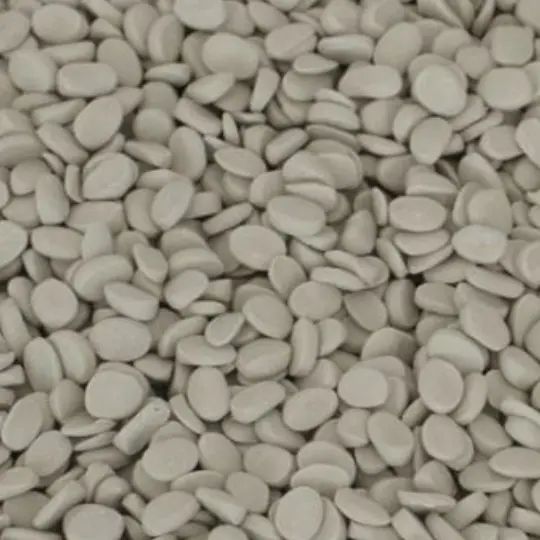

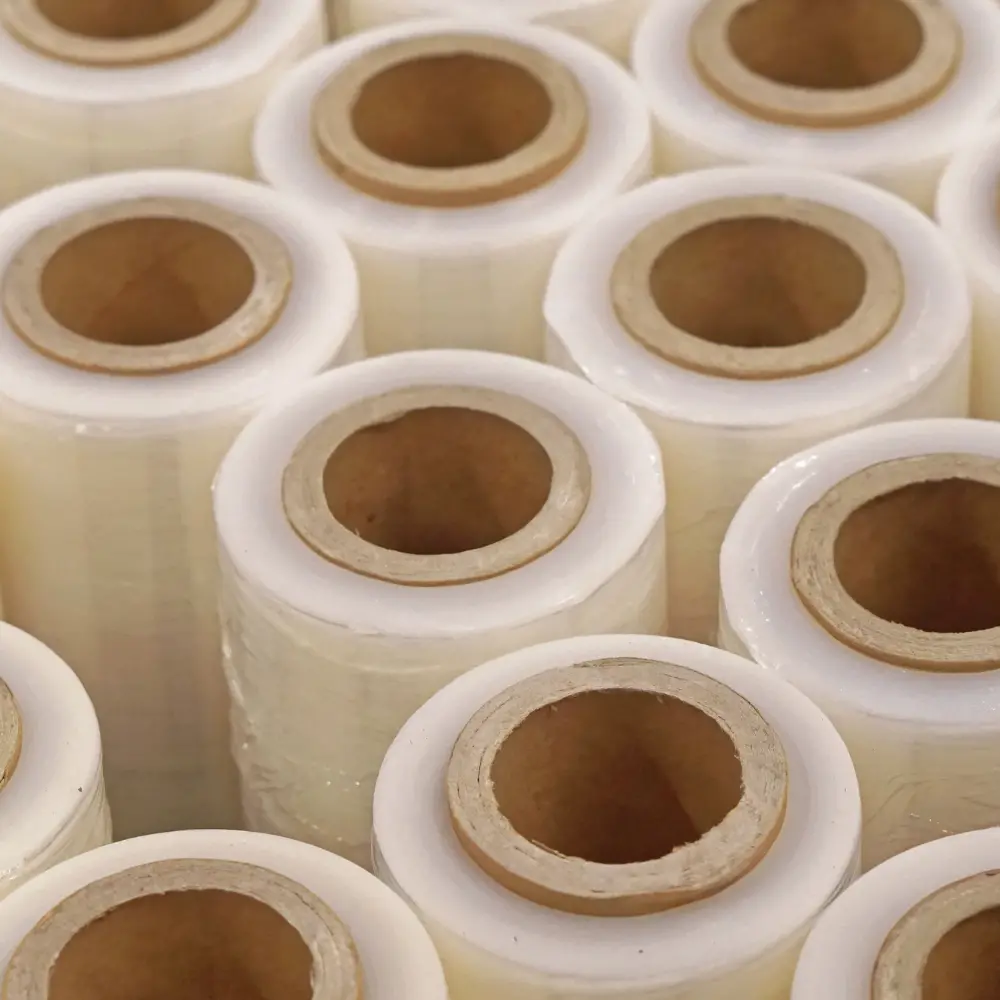

Antistatic Masterbatch | AS PE1027 | electrical components , Non woven , films |

Share